#Manual Tape Cutting Machine

Explore tagged Tumblr posts

Text

All across the world, there is a rush by marketeers to sell you new appliances. The last couple decades of increasingly-shitty build quality have failed to plump their margins enough, so now they're trying the carrot. Now, when you buy a refrigerator, it can be connected to the internet. Some ovens need to be connected to the internet, or they can't cook a turkey. If you went back in time and explained this state of affairs to someone in the Victorian Era, they'd shoot you.

When did our civilization lose its inherent distrust of machines pretending to be human? Half of our most popular science-fiction franchises are about a glad-handing, smiling robot trying to steal or murder our children. Now we're going to let a refrigerator lock down access to nutrients for those same children, because it couldn't resolve DNS? No more of this, I say, which is why I've started a new business.

Here at Appliance Endumbinators, our crack team of computer scientists, computer engineers, and angry people with hammers will work hard to remove any semblance of "intelligence" from your appliances. If you bought a new barbecue and it refuses to work unless you use factory-authorized propane, we'll rip its circuit boards out and splice together the miles of wiring that make up its nervous system until it gives in. We'll find your car and use an angle grinder to cut out the part of its positronic brain that obeys speed limits. And just for laughs, we'll duct-tape a thrift store alarm clock to your coffee maker, so that it can still have your brew ready for breakfast.

Book us in now, before the machines have their way with you. Become the master of your own home, comfortable with the most idiotic of automatons as you watch your neighbours suffer with thousand-page manuals, helpless service calls, and outsourced below-minimum-wage customer support just to toast a waffle.

491 notes

·

View notes

Text

I can't believe I haven't posted much-

ANYHOW! I've been getting into Dandy's World, it's honestly a hyperfixation of mine now >:>

I've been working hard and I have Poppy, Shrimpo, Rodger (my main) and Tisha! I want to get Goob, but I've been getting 100 ichor per run as an average, so it's gonna take 30 runs or so, not to mention the Goob research I need, and I can barely find him- But! This won't stop me! I'm going to research, maybe I can get Teagan for solo runs and Sprout or Cosmo for runs with everyone! I really like stragetizing, so my strageties I'm thinking about using under the cut. Feel free to share your ideas or use these ones :>

So for Rodger, he's a bit slower so I'm trying to get 100% on Razzle n Dazzle for the ribbon spool, because the clown horn gives me 10%+ walk and run on odd numbered floors, and the ribbon spool does the same for even floors. I wanna work for the dog plush as well, just so I can work with more stamina.

Teagan and Sprout would be good with a coin pouch and using the tape cards, Cosmo would be good with cardboard armor, so he doesn't get jumped by Goob or Scraps. It'll be hard to get bandages and medkits with my luck-

If I play as Toodles for the higher stealth, I should look into the wrench and machine manual/magnifying glass, because she has 2 for her extraction speed

Dandy plush would be amazing for Teagan/Sprout! But that's going to be near impossible for me to get, I struggle getting to floor 8 as is, and Twisted Dandy pops up at earliest, the 6th floor. But, the work would be worth it!

I should look into getting one of the mains, not sure who. Any ideas? (Oh and maybe Yatta, cuz if I keep getting attacked, I'll go out with a bang ig :'>)

#dandys world#dandy's world#dw rodger#dandy's world rodger#dw toodles#dandy's world toodles#dw sprout#dw cosmo#dw teagan#dandy's world sprout#dandy's world cosmo#dandy's world teagan

10 notes

·

View notes

Text

This particular mend turned out to be MUCH more complex, involved, and fussy than I really ever expected it to be at the outset. That said, after all the work where I focused on taking my time to get things just so, I found out that I'm quite capable of handling larger projects like this!

First up, here, before starting, my partner Razz and I sat down, and went through our clothes with a careful eye. More and more of her pants in particular were in need of little fixes here and there, and I figured rather than going about it all piecemeal and in no particular order, not accomplishing the fixing of clothes she needs, we put them together into an order of "most wanted fixes" to "least pressing fixes".

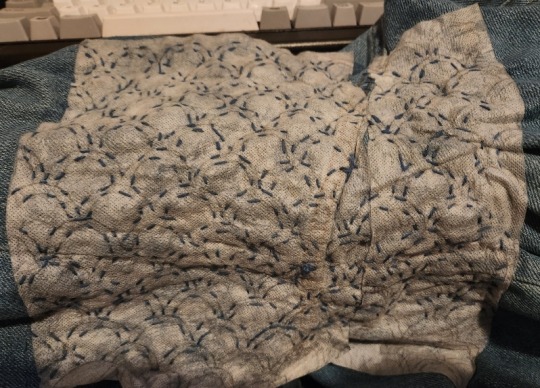

Once I had all that info, I settled in with a measuring tape, and got to identifying all the mends that needed to happen. For every piece that was more than, say, a few inches of rip, or of a shape that standard embroidery wouldn't cut it for a fix, I cut out a piece of patch fabric, with the intention of making use of these patches by doing sashiko mends.

Step 1: pin the hem of the patch down, initially hoping to run it through the sewing machine to have a nice hem! Sure, it was kinda fussy doing the quarter inch hems, since I hadn't really done this before, but it's not _too_ bad in hindsight!

Step 2: Realize that the sewing machine foot you have on hand got mixed up with a family member's in a move, and begrudgingly realize you have to re-pin the hemmed patch directly to the jeans being mended. Grumble, grumble! Oh well, at least this light blue thread is going to be really cute on the jeans, so there's that.

Step 3: stitch down the patch to the fabric, blissfully unaware that this big of a patch which interacts with the main seams four times like this is going to be a huge pain later!

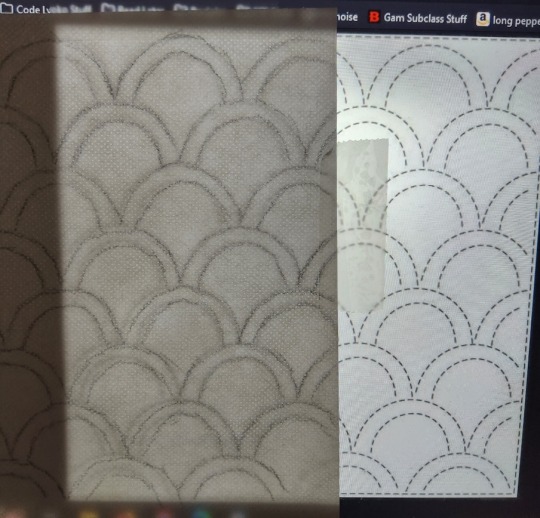

Step 4: with some clever use of tape and bumping the laptop brightness, make a tracing of the segaihana pattern onto the dissolvable backing. (I did realize later, mind you, that I could have just used something small and circular to draw this manually, but the tracing worked out just fine, so we take those!)

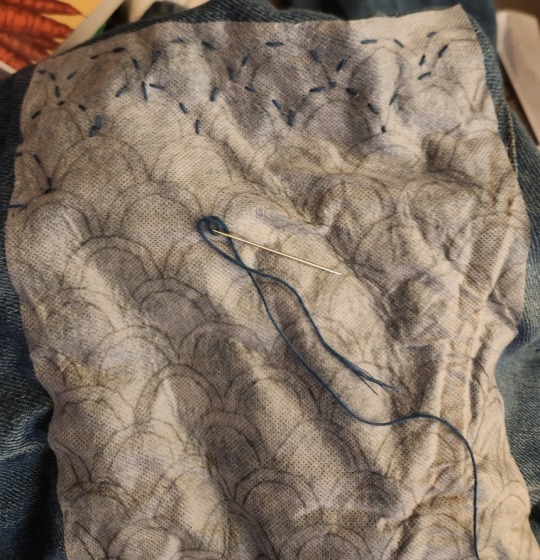

Step 5: get stitching, following the pattern on the backing! I get about this far before two things happen: first off, the sewing machine foot returned from family-home purgatory, and secondly, I realize that pushing this needle over and over with my bare hands is REALLY wearing out not only the muscles in my hands, but also thoroughly frustrating my skin, in the process.

So, as a little test of the sewing machine, I made this little palm thimble! the loop of thread on the left there loops around my middle finger, and then the denim takes the brunt of pushing the needle, instead of my poor fingies!

So, over the course of a few days, with a LOT of help from the palm thimble (some pieces even getting done on stream, go check out the vods: https://youtu.be/oeytUetT2Z0 and https://youtu.be/u6k-Yr4Vjn0) we get the first (major) panel done! Might not be super visible in these shots, but there is in fact a second piece to be stitched here!

So, after yet more tracing (which took a good bit more fuss, since I had to align it with the previous panel!) we find ourselves at step 6: do the second batch of stitching! Overall, I actually really enjoyed the way this piece came together, the segaihana pattern is super pretty to look at. Plus, I learned a LOT in doing this one, the big thing being, if you're going to have trouble on both sides of a thigh of a pair of jeans, even if the damage is spread evenly on either side, break the patches up along the main seam. Sewing through the many layers of that denim is particularly taxing, especially when I'm struggling to nail the positioning of the stitches to carry on a nice pattern!

#solarpunk#slow fashion#sashiko#embroidery#hand embroidery#fiber arts#fabric art#visible mending#sashiko mending#denim mend#diy craft#hand sewing#handmade#sewing#mending#fix your clothes#queue.queue#a thousand words#sproutleboople#nesterian lifestylings

36 notes

·

View notes

Text

CNC development history and processing principles

CNC machine tools are also called Computerized Numerical Control (CNC for short). They are mechatronics products that use digital information to control machine tools. They record the relative position between the tool and the workpiece, the start and stop of the machine tool, the spindle speed change, the workpiece loosening and clamping, the tool selection, the start and stop of the cooling pump and other operations and sequence actions on the control medium with digital codes, and then send the digital information to the CNC device or computer, which will decode and calculate, issue instructions to control the machine tool servo system or other actuators, so that the machine tool can process the required workpiece.

1. The evolution of CNC technology: from mechanical gears to digital codes

The Beginning of Mechanical Control (late 19th century - 1940s)

The prototype of CNC technology can be traced back to the invention of mechanical automatic machine tools in the 19th century. In 1887, the cam-controlled lathe invented by American engineer Herman realized "programmed" processing for the first time by rotating cams to drive tool movement. Although this mechanical programming method is inefficient, it provides a key idea for subsequent CNC technology. During World War II, the surge in demand for military equipment accelerated the innovation of processing technology, but the processing capacity of traditional machine tools for complex parts had reached a bottleneck.

The electronic revolution (1950s-1970s)

After World War II, manufacturing industries mostly relied on manual operations. After workers understood the drawings, they manually operated machine tools to process parts. This way of producing products was costly, inefficient, and the quality was not guaranteed. In 1952, John Parsons' team at the Massachusetts Institute of Technology (MIT) developed the world's first CNC milling machine, which input instructions through punched paper tape, marking the official birth of CNC technology. The core breakthrough of this stage was "digital signals replacing mechanical transmission" - servo motors replaced gears and connecting rods, and code instructions replaced manual adjustments. In the 1960s, the popularity of integrated circuits reduced the size and cost of CNC systems. Japanese companies such as Fanuc launched commercial CNC equipment, and the automotive and aviation industries took the lead in introducing CNC production lines.

Integration of computer technology (1980s-2000s)

With the maturity of microprocessor and graphical interface technology, CNC entered the PC control era. In 1982, Siemens of Germany launched the first microprocessor-based CNC system Sinumerik 800, whose programming efficiency was 100 times higher than that of paper tape. The integration of CAD (computer-aided design) and CAM (computer-aided manufacturing) software allows engineers to directly convert 3D models into machining codes, and the machining accuracy of complex surfaces reaches the micron level. During this period, equipment such as five-axis linkage machining centers came into being, promoting the rapid development of mold manufacturing and medical device industries.

Intelligence and networking (21st century to present)

The Internet of Things and artificial intelligence technologies have given CNC machine tools new vitality. Modern CNC systems use sensors to monitor parameters such as cutting force and temperature in real time, and use machine learning to optimize processing paths. For example, the iSMART Factory solution of Japan's Mazak Company achieves intelligent scheduling of hundreds of machine tools through cloud collaboration. In 2023, the global CNC machine tool market size has exceeded US$80 billion, and China has become the largest manufacturing country with a production share of 31%.

2. CNC machining principles: How code drives steel

The essence of CNC technology is to convert the physical machining process into a control closed loop of digital signals. Its operation logic can be divided into three stages:

Geometric Modeling and Programming

After building a 3D model using CAD software such as UG and SolidWorks, CAM software “deconstructs” the model: automatically calculating parameters such as tool path, feed rate, spindle speed, and generating G code (such as G01 X100 Y200 F500 for linear interpolation to coordinates (100,200) and feed rate 500mm/min). Modern software can even simulate the material removal process and predict machining errors.

Numerical control system analysis and implementation

The "brain" of CNC machine tools - the numerical control system (such as Fanuc 30i, Siemens 840D) converts G codes into electrical pulse signals. Taking a three-axis milling machine as an example, the servo motors of the X/Y/Z axes receive pulse commands and convert rotary motion into linear displacement through ball screws, with a positioning accuracy of up to ±0.002mm. The closed-loop control system uses a grating ruler to feedback position errors in real time, forming a dynamic correction mechanism.

Multi-physics collaborative control

During the machining process, the machine tool needs to coordinate multiple parameters synchronously: the spindle motor drives the tool to rotate at a high speed of 20,000 rpm, the cooling system sprays atomized cutting fluid to reduce the temperature, and the tool changing robot completes the tool change within 0.5 seconds. For example, when machining titanium alloy blades, the system needs to dynamically adjust the cutting depth according to the hardness of the material to avoid tool chipping.

3. The future of CNC technology: cross-dimensional breakthroughs and industrial transformation

Currently, CNC technology is facing three major trends:

Combined: Turning and milling machine tools can complete turning, milling, grinding and other processes on one device, reducing clamping time by 90%;

Additive-subtractive integration: Germany's DMG MORI's LASERTEC series machine tools combine 3D printing and CNC finishing to directly manufacture aerospace engine combustion chambers;

Digital Twin: By using a virtual machine tool to simulate the actual machining process, China's Shenyang Machine Tool's i5 system has increased debugging efficiency by 70%.

From the meshing of mechanical gears to the flow of digital signals, CNC technology has rewritten the underlying logic of the manufacturing industry in 70 years. It is not only an upgrade of machine tools, but also a leap in the ability of humans to transform abstract thinking into physical entities. In the new track of intelligent manufacturing, CNC technology will continue to break through the limits of materials, precision and efficiency, and write a new chapter for industrial civilization.

#prototype machining#cnc machining#precision machining#prototyping#rapid prototyping#machining parts

2 notes

·

View notes

Text

DIY Zippered Throw Pillows

Project by Brett Bara:

Throw pillows are another fantastic way to incorporate cute textiles and DIY flair into your home without a great investment of time or money. If you’ve ever gone into a fabric store and wanted to buy everything because it’s just all so gorgeous, then pillows are a great way to put those fabrics to work in your decor. Bold or loud prints that would be too much used in large scale (like in curtains) can be just right for a little pillow pop on a sofa or bed.

I’m going to show you how to make a zippered pillow cover, which is easier than it sounds, I promise. It looks super-professional AND has the added bonus of being easily changeable—I love the idea of making tons of different pillow covers and just swapping them out whenever you want a little change in a room.

The best part? You can make the pillow shown here in less than an hour! –Brett Bara

A Word on Zippers

Ok, I know you’re not going to believe me when I say this, but installing a zipper is REALLY EASY. (There are many ways to install a zipper —some more refined than others—the method I’m sharing here is basic and very simple!) BUT, if installing a zipper feels like it’s just too much, don’t give up. I’ll give alternate instructions at the end for how to make a pillow without a zipper. Everybody happy now? Let’s get started!

What You’ll Need

½ yard fabric (if your pillow is larger than 16”, you’ll need more fabric)

1 pillow form (buy this at a craft store or upholstery shop)

1 all-purpose zipper about 4” shorter than the edge of your pillow

Thread to match your fabric

Seam ripper

Sharp scissors

Straight pins

Tape Measure

Sewing machine

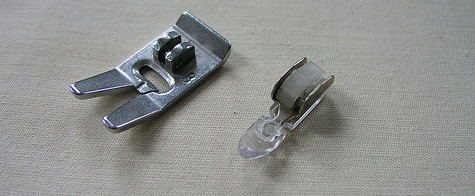

Zipper foot attachment for your sewing machine

Selecting and Preparing Fabric

Almost any type of fabric can be used for a throw pillow, but for beginners I recommend starting with medium-weight fabrics that are smooth in texture, like cottons or cotton-linen blends.

I’m using a Japanese print from the fantastic Etsuko Furuya for Echino line.

If your fabric is machine-washable, wash and dry it before sewing. This will pre-shrink the fabric, which is necessary to prevent the seams from puckering during future washings.

Finally, thoroughly iron the fabric before beginning.

Cutting

Cut two pieces of fabric that are the size of your pillow form plus 1” in length and 1” in width. So, if your pillow form is 12×16”, you’ll need two pieces of fabric that are 13×17”. This allows for ½” seam allowance on all seams.

Installing the Zipper

Place both pieces of fabric together with the right sides of the fabric facing each other and all corners aligned. (Be sure to situate both pieces so that the print pattern is facing in the same direction.)

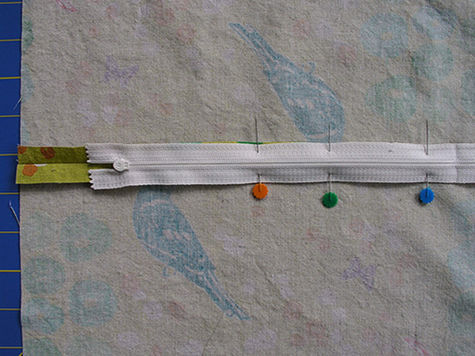

Center the zipper along what will be the bottom edge of the pillow, since you’ll want the zipper to be on the bottom edge of the finished pillow. (Here, my fabric is flipped with the bottom edge facing up, just to make it easier to work with). Place a pin near each end of the zipper, just INSIDE the metal stops at each end.

With a ½” seam allowance, sew the two segments on the outside of each pin. (This should be a short space of just a couple inches between the pins and the corners of the fabric.) Reinforce these seams by back-stitching at the beginning and end of each seam.

Next, change the stitch length on your machine to the longest length, which will allow you to baste the next seam. (Basting is sewing a long stitch which will later be removed; the long, loose quality of a basted stitch makes them easier to remove than regular stitches) With the stitch length set to long, simply sew the space in between the two short seams you just made. (Do not back-stitch to reinforce basted seams.)

Iron this seam open.

With the wrong side of the fabric facing up, place the zipper right-side down, aligning the zipper teeth directly over the seam. Pin it in place.

Change your machine’s presser foot to the zipper foot. Consult your manual for help with this if necessary; usually the feet snap off and on rather easily.

A zipper foot (shown here on the right) can be different for every sewing machine model, but it often looks like half of a standard presser foot (shown on the left). It allows you to sew right along the edge of the zipper teeth neatly and easily. The zipper foot has a little sliding part that changes it to a right or left position, so just slide it accordingly depending on whether you are sewing the right or left side of the zipper. (That means you have to pop off the zipper foot after sewing the right-side seam, slide the zipper foot thingie over to the left position, then pop the foot back on the machine. All this only takes a second once you get the hang of it!)

Note: Be sure your stitch length is back to normal length for the remainder of the sewing. Starting at the bottom of the zipper on the right side, with the zipper foot in the right-side position, sew down the side of the zipper. When you get near the end, stop the machine. Leave the needle in the work, but raise the foot, and gently move the zipper pull back behind the needle. Then lower the foot again and sew to the end of the zipper. Backstitch at the end of this seam.

Next, change the zipper foot to the left position, and repeat this process on the left.

And your zipper is installed! (That wasn’t so bad, right?) The seam is still basted closed, so from the right side, use the seam ripper to gently remove the basted stitches. (They’ll pop out really easily; just pick out any remaining thread pieces that are left dangling.)

Change back to the standard presser foot. Fold the two pillow halves so that they are aligned with right sides facing each other and all corners and edges meeting. Pin in place. Sew around all three sides with a ½” seam allowance. (The fourth side, of course, is the side with the zipper installed.)

Here’s how to sew around the corners: when you reach each corner, leave the needle in the fabric and raise the presser foot, then pivot the fabric 90 degrees, lower the presser foot again, and continue sewing.

Clip the fabric at the corners. (Removing the excess fabric here helps give you a nice, sharp corner once you turn the pillow inside out.)

Turn the pillow cover inside out, ironing the seams flat.

Insert the pillow form, and you’re done!

NOW FOR THE NO-ZIPPER PART

If you’d rather skip the zip, just use your sewing machine to sew the two pieces of fabric together around three edges, plus about 2” on each side of the fourth edge. Clip the corners and turn right-side out, iron the seam flat, then insert the pillow form. Using a needle and thread, hand-sew the opening closed. Of course, this pillow cover won’t be removable, but it will still be lovely!

18 notes

·

View notes

Text

What is Bagging Machine? - Payper India

A bagging machine is a type of industrial equipment used to automate the process of filling and sealing bags with various products. These machines are widely used in different industries, such as food, pharmaceuticals, chemicals, and agriculture, to efficiently package goods ranging from powders and granules to liquids and solids.

Image Ref : What is Bagging Machine — Payper India

Key Functions of Bagging Machines:

Filling: The machine accurately dispenses a pre-set amount of product into each bag. This can be achieved through various mechanisms, such as volumetric fillers, auger fillers, or weigh scales, depending on the nature of the product being packaged. Click here for Ref : www.payperindia.com

Sealing: After the bag is filled, the machine seals it to ensure the product is contained and protected. Sealing methods can include heat sealing, ultrasonic sealing, or using adhesive tapes, depending on the bag material and the product requirements. Click here for Ref : www.payperindia.com

Cutting/Trimming: Some bagging machines also trim excess material from the sealed bags to ensure a neat and uniform appearance. Click here for Ref : www.payperindia.com

Types of Bagging Machines:

Valve Bagging Machines: Designed for heavy-duty products such as cement, sand, or chemicals, these machines fill bags through a valve and then seal the valve to prevent leakage. Click here for Ref : www.payperindia.com

Open-Mouth Bagging Machines: Used for bulk products like grains, animal feed, or fertilizers, these machines fill pre-made bags that are manually or automatically positioned under the filling spout. Click here for Ref : www.payperindia.com

FIBC- Jumbo Bagging Machine: A jumbo bagging machine, or bulk bag filling machine, is designed to fill large bags (500–2000 kg) with bulk materials.

Why Payper ?

Payper India develops and manufactures bagging machines for all types of bulk solids such as powders or granulates. Other important product lines are palletizers and complete lines.

Our customers come from many different sectors, e.g., Chemical Industry, Agro-food Industry, Mining Industry and Building Industry. Payper India offers a comprehensive solution for each sector.

No need or demand is too small neither too big for us. We supply bagging machines for smaller industries with low volume requirements. We also provide complete turnkey projects for customers with high demands as to capacity and speed.

What matters to us is that our customer is comfortable and satisfied with the solution we have developed for them

Visit Payper at — https://www.payperindia.com/

Business LinkedIn -http://bit.ly/45Y1xMQ

Twitter — https://twitter.com/PayperIndia

Instagram — https://www.instagram.com/payperindia/

#payper#payperindia#baggingmachines#manufacturer#industry#machinery#robotics#palletisers#jumbobaggingmachine

2 notes

·

View notes

Text

Waste PP Yarn Cutting Machine

The newest and best automatic PP/HDPE cheese pipe cleaning machine was created in response to industry demand and rising labor costs. It replaces the labor-intensive, manual process of cutting tapes with scissors, a knife cutter, an electric hot wire, and a blade. This machine for cleaning PP/HDPE cheese pipes automatically cuts through yarns and tapes, separating the cheese pipes with great ease and collecting waste and cheese pipes in different boxes. Bobbins are not harmed or impacted by this cutting operation. These procedures are all completed quickly.

For more information contact us : +91- 9081802800, e-mail : [email protected]

#wastepp#yarncutting#recyclingmachine#polypropylene#textilewaste#recyclingequipment#sustainablemanufacturing#wastemanagement#ecommerce#commercial#branding#marketing#sales

1 note

·

View note

Text

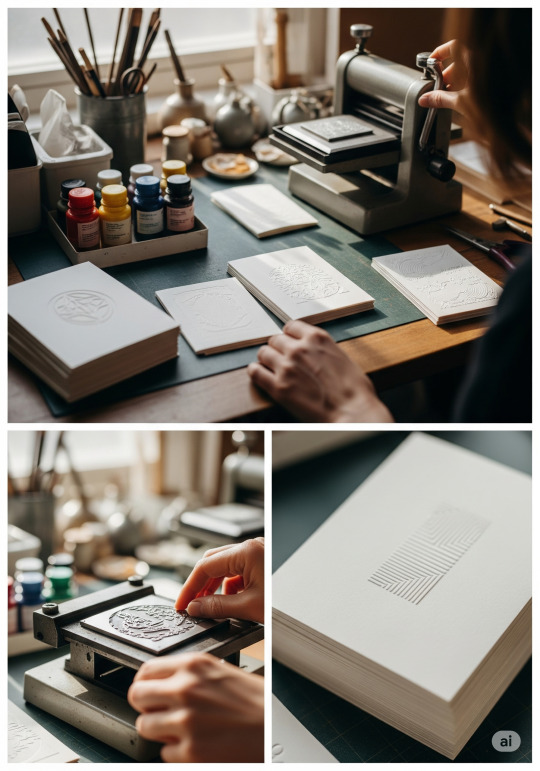

Pressed with Personality: DIY Letterpress and Embossed Cards

You’ve ironed, etched, stamped, stitched, and painted your way through this crafty jungle. But now, dear artisan, it's time to press your point—literally. Welcome to the beautifully tactile world of letterpress and embossing.

These techniques have been wooing paper lovers since the Renaissance, and they’re still the gold standard for elegance. Whether you’re crafting wedding invitations, thank-you notes, or business cards with bite—today’s projects are all about giving typography some serious texture.

🖨️ What Is Letterpress & Embossing?

Let’s define our new playthings:

Letterpress involves pressing inked, raised type into paper for a deep, crisp print.

Embossing creates a raised design (no ink necessary!) by pushing paper between two dies—one raised, one recessed.

Debossing is the reverse of embossing: it presses inward for a sunken-in effect.

For home crafters, we’re keeping it manual and DIY-friendly (read: no $20K letterpress machines today, folks).

🧰 What You’ll Need:

Blank cards or thick paper (at least 200gsm)

Embossing folder or DIY embossing stencil

Embossing tool (or blunt stylus)

Letter stamps or letterpress plates (can be 3D printed!)

Optional: Die-cutting/embossing machine (e.g. Sizzix, Cricut Cuttlebug)

Ink pad (for letterpress effect)

Washi tape, ruler, pencil, and a steady hand

🔠 Typography Tips for Pressed Crafts

Serif fonts shine here—think traditional, classy, and deeply readable.

All-caps serif gives authority to invitations and formal cards.

Avoid hyper-thin fonts—they don’t press well and may look like faint bruises on paper.

Bold script fonts can add elegance when embossed.

🧭 Step-by-Step: Handcrafted Press & Emboss Projects

✉️ Embossed Greeting Card

Sketch Your Layout Lightly draw guide lines in pencil.

Place Your Paper in Folder Or use a DIY stencil (cut from cardboard) for single words or initials.

Rub with Embossing Tool Trace the stencil edges with pressure—work slowly for smooth outlines.

Flip & Admire The reverse side should show a raised effect. Simple, clean, chic.

🖋️ Letterpress Effect (Without a Machine)

Ink Your Letters Using alphabet rubber stamps or carved wood blocks.

Align & Press Firmly Onto cardstock. Apply even pressure—use a book on top if needed.

Optional Deboss Touch While ink is still fresh, press a clean stylus around the edges of the letter to add depth.

🧠 Unique Fact of the Day:

The first movable type letterpress dates back to the 15th century, invented by Johannes Gutenberg. This single invention sparked the modern printing revolution—and yet here you are, doing it for fun, with ink-stained fingers and homemade stencils. The full-circle moment is chef’s kiss.

💌 Typography-Based Project Ideas

Thank-You Cards: Embossed initials or words like “GRATEFUL” or “YOU ROCK.”

Wedding Invitations: Classic serif fonts, letterpress-inked dates.

Quote Cards: Letterpress a motivational phrase, frame it, or slip it into a gift.

Mini Business Cards: Debossed logos + your name in clean serif = classy AF.

Gift Tags: Use small stencils to emboss monograms or festive words like “JOY” or “LOVE.”

✨ Crafting Wisdom:

For embossing: dampen paper very slightly—a light mist can help it mold better.

For letterpress: always test your ink pad and spacing on scrap paper.

Don’t be afraid to combine embossed designs with ink for mixed-media style.

🧪 Experiment Ideas:

Use metallic ink for a luxe letterpress.

Try blind embossing—no ink, just texture—for an ultra-minimalist vibe.

Pair embossed words with hand-lettered embellishments for a “hybrid typography” look.

🔤 Font Pick of the Day:

Try Playfair Display, Cormorant Garamond, or Lora for elegant serif type. For something whimsical, try Bodoni Moda or Libre Baskerville—they look amazing when pressed!

https://letterhanna.com/pressed-with-personality-diy-letterpress-and-embossed-cards/

0 notes

Text

Strapping & Taping Machine: The Ultimate Guide for Packaging Efficiency

In today’s fast-paced industrial world, businesses are continually looking for ways to optimize packaging processes. One of the most essential tools for improving productivity, ensuring safety, and minimizing packaging errors is the Strapping & Taping Machine. Whether you're managing logistics, manufacturing, or distribution, understanding these machines can significantly enhance operational efficiency.

This article explores everything you need to know about strapping and taping machines—how they work, their benefits, types, applications, and how to choose the best solution for your needs—all crafted in line with Google's 2025 SEO algorithm guidelines.

What is a Strapping & Taping Machine?

A Strapping & Taping Machine is a packaging device designed to secure packages using either plastic or steel straps (strapping) or pressure-sensitive adhesive tape (taping). These machines automate the packaging process, providing uniform, secure, and professional finishes that help in handling and transportation.

While strapping machines bind products with durable straps, taping machines seal boxes or cartons with tape. The combination of both ensures complete package integrity.

Types of Strapping & Taping Machines

1. Automatic Strapping Machines

These are ideal for high-volume packaging lines. They offer fast and consistent strapping and are integrated with conveyors for a seamless workflow.

2. Semi-Automatic Strapping Machines

Perfect for medium-sized operations, these require manual product positioning but automate the strapping process.

3. Manual Strapping Tools

Cost-effective and portable, these tools are suitable for low-volume packaging needs.

4. Carton Sealing Machines (Taping Machines)

These are specialized for sealing boxes using BOPP tape. They come in automatic and semi-automatic variants to match different production scales.

5. Combination Systems

Advanced solutions that combine both strapping and taping functions, perfect for operations that need both processes in one go.

Key Benefits of Strapping & Taping Machines

✅ Enhanced Packaging Speed

These machines significantly reduce the time taken to strap or tape packages, enabling faster throughput.

✅ Consistent Seal Quality

Automation ensures uniformity, reducing human error and enhancing the aesthetic and structural integrity of packages.

✅ Labor Cost Reduction

With minimal human intervention, businesses can cut down on labor costs and allocate human resources to other critical areas.

✅ Improved Safety

Machines provide a safer packaging process, especially for heavy-duty applications, by minimizing manual handling.

✅ Better Load Securing

Strapping machines tightly secure loads, reducing damage during transit and storage.

Applications of Strapping & Taping Machines

E-commerce Fulfillment Centers

Logistics & Warehousing

Food & Beverage Packaging

Pharmaceuticals & Chemicals

Electronics & Appliances

Automotive Parts & Components

These machines are versatile and fit for various industries where efficient and secure packaging is essential.

How to Choose the Right Strapping & Taping Machine

🔍 Assess Packaging Volume

High-volume operations benefit from fully automatic systems, while small businesses may find semi-automatic or manual tools more suitable.

🔍 Material Type

Consider whether your products require plastic strapping, steel strapping, or different tape grades.

🔍 Box Dimensions

Select machines that can accommodate the range of package sizes you deal with regularly.

🔍 Space Availability

Evaluate your workspace and choose compact or modular machines if floor space is limited.

🔍 Maintenance & Support

Choose a machine that's easy to maintain and supported by good technical documentation or remote diagnostics.

Latest Trends in Strapping & Taping Machines (2025)

IoT Integration: Modern machines are now equipped with IoT sensors for real-time monitoring and predictive maintenance.

Eco-Friendly Tapes & Straps: There is a growing shift towards biodegradable and recyclable packaging materials.

Smart Automation: Integration with conveyor systems and automated guided vehicles (AGVs) is becoming more common.

Energy Efficiency: New models are designed to consume less power while delivering higher output.

SEO Tips: Why Target the Keyword "Strapping & Taping Machine"?

Targeting the keyword Strapping & Taping Machine aligns with buyer intent, especially for B2B decision-makers searching for industrial packaging solutions. Including variations such as automatic strapping machine, carton taping machine, packaging automation tools, and industrial taping systems can help broaden your SEO reach while maintaining relevance.

0 notes

Text

The Future of Interior Protection: Smart Barriers and High-Tech Dust Control

As technology continues to transform the construction and renovation industries, Interior Protection is also undergoing a quiet revolution. What was once a simple tarp-and-tape job is evolving into a sophisticated system of smart barriers, high-efficiency filters, and real-time air quality monitoring.

In this blog, we’ll explore the exciting future of Interior Protection—from intelligent containment systems to cutting-edge dust control technologies—and why it matters more than ever for safety, sustainability, and regulatory compliance.

Why Interior Protection Is More Important Than Ever

Construction and renovation projects don’t always happen in empty buildings. Work often takes place in:

Active retail spaces

Operating healthcare facilities

Food manufacturing plants

Occupied office environments

In these settings, Interior Protection isn't optional—it's essential. It safeguards workers, equipment, and building occupants from:

Airborne dust and debris

Contaminants like mold or asbestos

Cross-contamination in sensitive environments

Damage to surfaces, ceilings, or inventory

The demand for more effective and intelligent protection systems is fueling innovation in the industry.

Smart Barriers: The Next Generation of Containment

Traditional barriers are being replaced—or at least upgraded—with smart interior protection systems that offer automation, adaptability, and monitoring.

Key Features of Smart Barriers:

Modular Design: Easily reconfigured on-site as the project evolves.

Sensor Integration: Embedded sensors can track air quality, temperature, and pressure differentials.

Automated Sealing Mechanisms: Ensure perfect containment without constant manual adjustment.

Connectivity: Systems that send alerts if containment is breached or conditions change.

These smart barriers are especially valuable in hospitals, clean rooms, and food processing plants where maintaining strict environmental control is crucial.

High-Tech Dust Control Systems

Dust isn't just a nuisance—it’s a serious health hazard and regulatory concern. New dust control technologies are setting higher standards for interior protection.

Innovative Dust Control Methods Include:

HEPA-filtered Negative Air Machines: Capture 99.97% of dust particles and maintain negative pressure to contain pollutants.

Electrostatic Dust Suppression: Uses static charge to draw particles out of the air.

Real-Time Air Quality Monitors: Measure and log particulate levels to prove compliance and performance.

Portable Dust Containment Units: Self-contained enclosures with built-in air filtration and mobility.

Together, these technologies make Interior Protection more effective, especially in sensitive or regulated environments.

Sustainability Meets Interior Protection

With growing pressure for eco-friendly practices in construction, the future of Interior Protection is also greener. Innovations include:

Reusable containment panels instead of single-use plastic sheeting

Low-VOC adhesives and sealants for dust walls

Energy-efficient air scrubbers

Digitally monitored systems that reduce waste by alerting teams only when maintenance or replacement is needed

These sustainable practices help reduce landfill waste and carbon footprint—while keeping projects safe and compliant.

Looking Ahead: What to Expect

Here’s where Interior Protection is headed in the next few years:

AI-powered predictive maintenance for containment systems

Smartphone-connected sensors for remote monitoring

Integration with Building Management Systems (BMS)

Widespread use of prefabricated, ready-to-install protection kits

As the line between technology and construction continues to blur, Interior Protection will become smarter, safer, and more seamless than ever before.

Conclusion

The future of Interior Protection is not just about dust control—it's about intelligent systems that enhance safety, efficiency, and environmental responsibility. As regulations tighten and expectations rise, investing in high-tech, smart barrier systems will become a competitive advantage for contractors, property managers, and facility operators alike.

0 notes

Text

Unlock What’s Rightfully Yours: The Smarter Way to Recover Unclaimed Assets

In today’s fast-paced financial world, millions of dollars in unclaimed assets go unnoticed, locked away in forgotten bank accounts, dormant investments, uncashed checks, and more. For organizations, administrators, fiduciaries, and even governments, these hidden funds can represent significant unrealized value. But tracking them down through traditional methods can be a frustrating maze of red tape and outdated systems.

That’s where AssetFynd comes in.

Smarter Searches. Faster Results.

At AssetFynd, we believe that reclaiming what’s yours shouldn’t be a complicated guessing game. That’s why we’ve revolutionized the way unclaimed property is recovered. Our proprietary high-speed algorithms and intelligent search capabilities do in seconds what manual searches can take weeks to achieve.

No more sifting through dozens of government websites or outdated databases. AssetFynd uses AI and machine learning to connect the dots across hundreds of millions of global asset records—accurately, efficiently, and with minimal effort on your part.

Bridging the Gap Between Lost Assets and Legal Owners

Using cutting-edge technology, we close the loop between lost financial property and its rightful owner. Whether you're a corporation trying to balance your books, a trustee locating dormant funds, or a charity retrieving legacy gifts, AssetFynd is your dedicated partner in asset recovery.

Our platform is designed for:

Corporations seeking to reclaim overlooked revenue

Trustees and fiduciaries managing estates and trusts

Charities recovering unallocated donations

Governments managing unclaimed funds

Administrators streamlining asset audits

Global Reach. Local Precision.

AssetFynd offers a truly global solution with the precision and reliability needed to meet local legal and regulatory standards. Our extensive database includes both domestic and international asset records—giving you the confidence to search once and search right.

Why Choose AssetFynd?

Speed: Our intelligent algorithms cut down search times dramatically.

Accuracy: AI-powered matching ensures results are relevant and reliable.

Convenience: One platform. Billions of records. Unlimited potential.

Support: We’re with you every step of the way, from discovery to claim.

Reclaim More, Stress Less

Don’t let forgotten funds stay forgotten. Join the growing list of institutions, professionals, and organizations who are turning to AssetFynd for the most effective way to recover what’s rightfully theirs.

Let technology do the heavy lifting—start your asset recovery journey with AssetFynd today.

0 notes

Text

Invisible Strength, Visible Quality: What Makes a Gypsum Board Brand Truly Stand Out

Step into a finished interior — clean ceiling lines, crisp partitions, sharp corners. Now look closer. What’s making that finish possible?

Not the paint. Not the lighting. It’s the gypsum board underneath — invisible to the client, but everything to the execution.

That’s why industry leaders don’t just buy boards by size or price. They choose boards by performance, reliability, and long-term finish integrity.

And when quality, consistency, and nationwide supply come together, one name consistently rises: Buildwell — regarded by professionals as the Best Gypsum Board Brand in India for projects where the finish must match the promise.

“Invisible Strength” – Why the Board Behind the Paint Defines the Finish You See

A perfect finish starts long before primer hits the surface. It starts with the right core, the right edges, the right paper, and the right fit.

That’s where Buildwell makes its mark — by delivering a gypsum board that:

Cuts clean

Fixes fast

Holds strong

Finishes smooth

And does it consistently, across cities, climates, and construction styles.

What Makes Buildwell the Best Gypsum Board Brand in India?

Let’s break it down based on real-site impact:

✅ 1. Strong Paper Lamination for Seamless Jointing

Buildwell boards use high-strength face paper bonded with precision to the gypsum core, giving you:

Fewer jointing compound failures

Stronger tape grip

Less sanding after compound application

Cleaner final paint appearance

No joint bubbling. No shadow lines under downlights.

✅ 2. Crack-Resistant Core for Long-Term Stability

The internal composition is engineered to minimize expansion/contraction due to climate, ensuring:

No edge cracks

No board warping

Better alignment across large ceilings or partition grids

Especially critical for sites exposed to both dry heat and post-install AC cooling.

✅ 3. Clean Cutting & Easy Fixing

Buildwell gypsum boards respond well to manual and machine cutting, producing:

Smooth edges

Minimal dust

Easy alignment during fitting

Better screw holding capacity

Less material loss. Fewer rejected pieces.

✅ 4. Available in Full Range of Types & Sizes

Whatever your need — Buildwell has it:

Regular Boards – for dry interiors and standard ceiling work

Moisture-Resistant (MR) Boards – for kitchens, bathrooms, service ducts

Fire-Retardant (FR) Boards – for safety zones, shafts, fire-compliant walls

Available in standard 12.5mm thickness with multiple sizes as per BOQ.

One brand, all variants = faster approvals, fewer site-level changes.

✅ 5. Perfect Match with Buildwell System Products

Buildwell boards are designed to integrate with:

Buildwell jointing compound

Drywall screws

Metal framing

Ceiling tiles

Gypsum plaster and bond

Using everything from the same brand gives your project team complete material compatibility — eliminating site adjustments and post-handover surprises.

Where Buildwell Boards Make the Biggest Difference

🏢 Corporate Fit-Outs

Cleaner ceiling finishes, stronger edge joints, fewer complaints during walkthrough.

🏘️ Group Housing

Standardized finish quality across flats and towers with less material loss floor-by-floor.

🏫 Institutions & Schools

Impact-resistant performance and easy installation across partition-heavy interiors.

🏥 Healthcare Spaces

Smooth finish, MR options, and zero surface cracking for hygienic interiors.

🏬 Retail Spaces

Faster workability and better stability under accent lighting.

In every case, Buildwell ensures the gypsum board does what it’s supposed to: disappear from view, but hold everything together.

Why Contractors Choose Buildwell Again and Again

Boards that don’t crack while cutting

No delays due to board warping or misalignment

Consistent supply across project zones

Finish support and compatibility across the entire ceiling system

Minimal patchwork required during final handover

That’s why it’s considered the best gypsum board brand in India — because it helps contractors deliver perfect results with less pressure.

Final Word: The Best Interiors Start with the Right Board

Your painter may get the praise. Your designer may get the glory. But your gypsum board? It holds everything in place — quietly, reliably, invisibly.

Buildwell doesn’t just sell boards. It delivers project confidence.

That’s what makes it the best gypsum board brand in India — for homes, hotels, hospitals, or head offices that need finishes to last.

🌐Explore Ceiling Products at Buildwell.in

📧 Email: [email protected] 📲 WhatsApp: 7900336699 📞 Toll-Free: 18001028031

0 notes

Text

POF Shrink Film by Triveni Packaging – Flexible, Clear & Reliable Packaging for Everyday Products

Packaging is more than just covering a product—it's about showcasing your brand’s identity, preserving quality, and making that all-important first impression count. Whether you're sealing bakery goods, electronic accessories, or retail bundles, your packaging needs to look great, perform well, and stay reliable. This is where POF shrink film shines—and why countless businesses across the UAE trust Triveni Packaging Trading Co. LLC for their packaging needs.

For over three decades, Triveni Packaging has partnered with businesses in the UAE, helping them improve their packaging operations with durable, professional-grade materials. As a respected packaging materials supplier and packaging machine supplier, we take pride in offering high-quality POF shrink film that delivers on all fronts: clarity, strength, and versatility.

Why UAE Businesses Are Choosing POF Shrink Film

Not all shrink films are made equal. Traditional materials can be brittle or cloudy, but POF shrink film stands out for its clear finish, superior strength, and food-safe properties. It wraps tightly around your product, creating a smooth and secure seal that won’t split or degrade during transport. It’s even safe for direct contact with food—ideal for anything from fresh produce to frozen entrees.

Companies love POF because it helps cut down on waste, reduces tape use, and creates a professional presentation. Customers appreciate it for its neat, tamper-evident look that builds trust in the product. In short, it’s a win-win solution.

And because our POF shrink film works seamlessly on manual, semi-automatic, and fully automatic machines, it fits easily into any operation—whether you're a small startup or a large production facility.

A Flexible Fit Across Industries

One of the key reasons POF shrink film is so widely adopted across the UAE is its versatility. This versatile packaging solution is trusted across a wide variety of industries in the UAE, thanks to its adaptability and consistent performance:

Food and beverage – For neatly wrapping fruits, baked items, or frozen meals.

Retail and cosmetics – Used for attractive product bundles, skincare sets, and electronics.

Healthcare and pharmaceuticals – Perfect for packaging hygiene products, medical kits, or over-the-counter items.

Logistics and e-commerce – Helps group products together and ensures safe delivery to customers.

With its high-clarity finish and durable protection, our POF shrink film not only elevates the look of your product but also enhances its shelf life and appeal.

Why Work with Triveni Packaging?

At Triveni Packaging, we understand that good packaging goes beyond just materials—it’s about getting the right fit, the right service, and the right results. That’s why we act as more than just a vendor.—offering custom recommendations, installation support, and continued guidance as your needs evolve.

Here’s what makes us different:

We help you choose the best film thickness, width, and perforation for your product.

Our team ensures smooth integration with your existing machines.

We keep a large inventory of films, tapes, and protective packaging materials for fast delivery across the UAE.

Our technical support is just a call away, helping to keep your lines running smoothly.

As a leading packaging materials manufacturer and long-time player in the UAE’s packaging industry, our experience helps us tailor solutions that work—not just in theory, but in the real world of fast-moving supply chains.

Serving the UAE with Reliability and Speed

Located right here in the UAE, we understand the demands of local industries and are equipped to deliver quickly to clients across Dubai, Abu Dhabi, Sharjah, and beyond. Our clients include food manufacturers, cosmetic brands, pharmaceutical companies, and logistics providers—all looking for a packaging partner that delivers on time and on promise.

Thanks to our decades of expertise, we’ve become a trusted name among packaging materials suppliers, packaging machine suppliers, and protective packaging specialists. From the first roll of film to ongoing maintenance and support, we stay committed to helping your business grow.

Not Just POF—Complete Packaging Solutions

While our POF shrink film remains a customer favorite, it’s just one part of our wide offering. We also provide Cryovac shrink film, carton sealing machine, and a complete line of protective packaging materials to support every stage of your packaging line.

With Triveni, you get more than products—you get peace of mind, industry know-how, and a team that truly cares about the success of your packaging.

Let’s Talk Packaging

Looking to upgrade your packaging game? Whether you’re wrapping a new product line or scaling up production, Triveni’s POF shrink film is the clear choice for strength, clarity, and efficiency.

Get in touch with Triveni Packaging Trading Company LLC today—and see why so many businesses across the UAE count on us as their absolute packaging solutions company.

#pof shrink film#pof shrink film in uae#pof shrink film suppliers in uae#pof shrink film manufacturers in uae#triveni packaging#triveni packaging uae

0 notes

Text

Mattress Border Machine: Top 5 Advanced Systems for Edge Reinforcement in 2025

Mattress Border Machine: Top 5 Advanced Systems for Edge Reinforcement in 2025

What Is a Mattress Border Machine?

youtube

A mattress border machine is specialized equipment used in mattress manufacturing that handles the creation, quilting, and attachment of the vertical side panels (borders) of mattresses. These machines help streamline production by automating what would otherwise be labor-intensive processes.

Core Functions of Mattress Border Machines

The primary purpose of a mattress border machine is to create professionally finished edges for mattresses. These machines can perform several key functions depending on the model. Most border machines can quilt decorative patterns into the border material, adding both aesthetic appeal and structural integrity to the mattress sides.

Some advanced models like the M-4000 and M-4400 are designed for high-speed production, capable of quickly processing large volumes of mattress borders.

Border machines can also measure and cut border sections to precise specifications, ensuring consistency across production runs. This precision is crucial for creating professional-looking mattresses that meet quality standards.

Many modern border machines can also install zippers, which is essential for mattress protectors and mattresses with removable covers. This feature has become increasingly important as demand for accessible, cleanable mattress products grows.

Key Components and Structure

Border machines typically consist of several important components working together. The sewing head is one of the most crucial parts - machines like the DZ-52 feature multi-needle systems designed specifically for wider border sewing applications.

The feeding mechanism moves fabric through the machine at a controlled rate. Some advanced models include auto-feeding systems with edge-alignment technology that ensures borders remain straight and even.

Most border machines have pattern programming capabilities that allow manufacturers to create various decorative stitching patterns. These can range from simple rectangular designs to more complex triangle patterns, as seen in the CC-1A model.

Material detection sensors help prevent jams and ensure proper alignment throughout the sewing process. These sensors are particularly important when working with different fabric thicknesses or when attaching rubber bands in mattress protector production.

How Mattress Border Machines Work

The operation begins with loading the border fabric onto the machine. For roll-to-roll systems from Global Systems Group (GSG), this involves setting up continuous fabric rolls for high-volume production.

The machine then positions the fabric correctly using alignment tools and sensors. This step is crucial because even slight misalignments can result in visible defects in the finished mattress.

Next, the multi-needle sewing head creates decorative stitching patterns across the border material. This not only enhances the appearance but also reinforces the border for durability. Machines like the DZ-52 are specialized for this precise function.

For borders requiring zippers, specialized attachments on machines like the Richpeace Border Zipper Sewing Machine automatically position and attach zipper components. This automation dramatically reduces the time needed compared to manual zipper installation.

Finally, cutting mechanisms measure and cut the finished borders to the exact specifications needed for each mattress size. The precision of these cuts ensures proper fit when the borders are attached to the mattress panels.

Types of Mattress Border Machines

youtube

Mattress border machines come in several varieties, each designed to handle specific tasks in mattress manufacturing. These machines stitch designs, attach tapes, and create borders that give mattresses their finished look and structure.

Manual Mattress Border Machines

Manual border machines are the most basic type and require significant operator involvement. These machines need workers to guide the fabric through the stitching process by hand. While they're slower than other options, they offer great flexibility for custom work and small production runs.

Manual machines are usually more affordable, making them ideal for smaller mattress manufacturers or start-up operations. They typically include simple serging machines that finish the edges of the border fabric and basic stitching equipment.

The learning curve for manual machines is relatively short, but productivity depends heavily on operator skill. Most can handle various fabric types and thicknesses, though they lack the advanced pattern capabilities of automated systems.

Automatic Mattress Border Machines

Automatic border machines represent the cutting edge of mattress manufacturing technology. These sophisticated systems can create complex patterns and designs with minimal human intervention. They're programmable via touchscreens, allowing operators to select from pre-loaded designs or create custom patterns.

These machines dramatically increase production speed and consistency. Many automatic models can stitch logos, decorative patterns, and functional elements like handles or ventilation holes.

The initial investment for automatic machines is substantial, but they significantly reduce labor costs and material waste. Modern automatic border machines often include:

Multiple needle configurations

Automatic thread tension adjustment

Memory for storing numerous patterns

Precision cutting capabilities

Integrated tape-edge application

Semi-Automatic Mattress Border Machines

Semi-automatic border machines bridge the gap between manual and fully automatic systems. They automate certain parts of the process while still requiring some operator guidance.

These machines usually have motorized fabric feeding mechanisms but need workers to position materials and monitor operations. They're faster than manual machines but more affordable than fully automatic systems.

Semi-automatic machines often include features like:

Programmable stitch patterns

Automatic thread cutting

Adjustable speed controls

Guided sewing paths

They're ideal for medium-sized manufacturers looking to balance efficiency with budget constraints. Most semi-automatic models can handle a wide range of border materials, from traditional cotton ticking to modern synthetic blends.

Technical Specifications Explained

youtube

When selecting a mattress border machine, understanding the technical specifications is crucial for making an informed decision. These specifications directly impact production efficiency, cost-effectiveness, and the quality of your finished mattresses.

Sewing Speed and Performance

The sewing speed of a mattress border machine significantly affects your production capacity. Most modern machines operate between 2,000 to 3,500 stitches per minute (SPM), with high-end models reaching up to 5,000 SPM.

I've found that machines with adjustable speed settings offer the best versatility, allowing operators to slow down for intricate patterns or speed up for straight seams. For example, the CC-1A Mattress Border Vertical Stitching Machine features programmable patterns that help maintain consistent quality regardless of speed.

Look for machines with automatic thread tension adjustment systems. These systems help maintain stitch quality even as the speed changes, which I've seen reduce production errors by up to 30%.

Power and Energy Consumption

Power requirements for mattress border machines typically range from 0.75 kW to 2.5 kW, depending on the model and capabilities. Single-phase machines are suitable for smaller operations, while three-phase power is standard for industrial settings.

Energy efficiency has become a major consideration in recent years. I've noticed newer models incorporate energy-saving features like:

Servo motors instead of clutch motors (up to 70% more efficient)

LED lighting systems (reducing power consumption by 80% compared to traditional lighting)

Automatic sleep modes when idle for more than 5 minutes

When calculating operational costs, don't overlook power consumption. A machine using 0.5 kW less per hour can save approximately $500 annually in a standard production environment.

Sewing Thickness Capabilities

The ability to handle various material thicknesses is perhaps the most critical specification for a mattress border machine. Standard machines can typically handle materials from 8mm to 30mm thick.

I recommend looking for machines with:

Adjustable presser foot height

Strong needle penetration power

Variable feed dog settings

The best machines offer electronic thickness detection that automatically adjusts settings based on the material. This feature has saved me countless hours of manual adjustments when switching between different mattress types.

For specialized applications like pillow-top borders, ensure your machine can handle at least 40mm thickness. Some advanced Mattress Border Machines now incorporate ultrasonic sensors that measure thickness in real-time, adjusting thread tension accordingly for perfect stitches every time.

Key Features of Quality Mattress Border Machines

Modern mattress border machines come with several essential features that enhance production efficiency and product quality. These machines have evolved to include adjustable settings, precision cutting tools, and intuitive controls that simplify the manufacturing process.

Adjustable Fabric Width Options

When I shop for a mattress border machine, adjustable fabric width capability is one of the first features I look for. Quality machines offer width adjustments from 6 to 15 inches, accommodating different mattress sizes from twin to California king.

The best models include quick-change mechanisms that let operators switch between width settings in under a minute. This saves valuable production time when manufacturing different mattress models.

I've found that machines with digital width indicators provide more precision than manual adjustment systems. This precision prevents fabric waste and ensures consistent borders throughout production runs.

Some premium machines even offer programmable presets for different mattress models, eliminating setup errors when switching between products. This feature is especially valuable for factories that produce multiple mattress lines.

Advanced Cutting Mechanisms

The cutting system is what truly separates basic from quality border machines. Top-tier models use hardened steel blades that maintain sharpness through thousands of cutting cycles.

I prefer machines with automatic blade sharpening features that maintain cutting precision without production delays. This eliminates the jagged edges that can affect the final appearance of the mattress.

Laser-guided cutting systems provide accuracy down to 0.5mm, ensuring perfectly aligned fabric panels. This precision is crucial for creating professional-looking borders that enhance the mattress's visual appeal.

Many modern border machines incorporate servo-driven cutting mechanisms that reduce fabric waste by up to 15% compared to older mechanical systems. This efficiency translates directly to cost savings in material usage.

User-Friendly Control Systems

The control system forms the brain of any mattress border machine. I've worked with machines featuring touchscreen interfaces that display all critical operating parameters on a single screen.

Intuitive icons and color-coded controls make operation possible even for new workers with minimal training. This reduces the learning curve and helps maintain production speeds.

The best machines include memory functions that store settings for different border styles and fabrics. With a push of a button, operators can switch between quilted, plain, or decorative border types.

Error detection systems alert operators to problems like fabric jams or thread breaks before they cause production delays. These early warnings prevent damage to the machine and materials.

Remote diagnostics capability is becoming standard on premium models, allowing technicians to troubleshoot issues without visiting the factory floor. This minimizes downtime when technical problems arise.

Customization Options for Manufacturers

Mattress border machines offer a wide range of customization options for manufacturers looking to stand out in the competitive bedding market. These features allow production of unique mattress borders that can help establish brand identity and meet specific customer preferences.

Customizable Design Elements

The best mattress border machines let manufacturers create distinctive designs that reflect their mattress brand personality. I've seen machines that offer digital printing capabilities, allowing for vivid logos and patterns directly on borders. Some advanced models include screen printing and heat transfer options for more complex designs.

Border width adjustment is another key feature. Most modern machines can handle various border dimensions, typically ranging from 8 to 16 inches. This flexibility helps manufacturers create everything from slim, minimalist borders to plush, luxurious ones.

Color options are practically unlimited with today's technology. Many machines support multi-color stitching patterns and decorative elements that can be programmed through user-friendly interfaces.

Texture variations are also possible, with some machines offering quilting, embossing, or raised pattern capabilities that add both visual and tactile appeal to the final product.

Integration with Other Mattress Equipment

Modern mattress border machines are designed to work seamlessly with other production equipment. I've found that the most efficient setups include border machines that integrate directly with quilting systems, creating a streamlined workflow.

Compatibility with existing fabric feeding systems is crucial. The best machines accept materials from various sources and can be positioned in-line with cutting and sewing stations. This reduces handling time and minimizes production errors.

Digital connectivity features are becoming standard in high-end border machines. Many now include software that connects to central production management systems, allowing manufacturers to track efficiency, manage patterns, and schedule maintenance.

Some border machines can also be integrated with quality control systems that scan for defects while creating decorative elements, ensuring that only perfect borders move forward in the production process.

Essential Accessories and Attachments

Getting the most from your mattress border machine requires the right accessories. These attachments not only improve the quality of your finished mattress but also increase production efficiency and give you more creative options for border designs.

Guides and Feeders

The right guides and feeders make a huge difference in border production quality. Tape guides are essential for keeping the binding tape properly aligned as it feeds into the machine. I've found that adjustable guides work best since they can accommodate different tape widths.

Material feeders help maintain consistent tension on the border fabric as it moves through the machine. Most quality machines come with standard feeders, but upgrading to pneumatic feeders can dramatically improve consistency, especially when working with thicker materials.

Thread stands and holders are often overlooked but crucial accessories. Multi-spool stands allow for quick thread changes and reduce downtime between jobs. For high-volume production, I recommend investing in tension-controlled thread guides that prevent thread snapping and uneven stitches.

Cutting Attachments

Cutting attachments streamline the border finishing process by automating what would otherwise be manual cutting tasks. Automatic cutters with adjustable depth controls are essential for clean, consistent cuts across different fabric thicknesses.

The most valuable cutting attachment I've used is the programmable end cutter. This tool automatically cuts the border at predetermined lengths, eliminating measurement errors and saving significant time. Many models now include laser guides that ensure perfectly straight cuts every time.

Thread trimming attachments are also worth the investment. These small but mighty add-ons clip excess thread after sewing, giving borders a clean, professional finish without manual trimming. For mattress manufacturers producing hundreds of units daily, this small enhancement can save hours of labor.

Binding and Edge Trimming Devices

Binding devices are crucial for creating clean, durable mattress edges. Automatic binders fold and feed tape along the mattress edge while the machine stitches it in place. I've seen how upgrading from manual to automatic binders can cut production time nearly in half.

Edge trimming devices ensure uniform borders by removing excess material as the binding is applied. Look for adjustable trimmers that can handle different fabric types without fraying or damaging the material.

Decorative binding attachments allow for creating distinctive border designs like the faux tape edge mentioned in the search results. These specialized devices can apply decorative piping or create unique stitch patterns that make your mattresses stand out in the market.

Production Efficiency and Speed

Mattress Border Machines significantly boost manufacturing capacity while maintaining quality. Modern machines combine advanced technology with robust engineering to transform how mattress edges are sewn.

Increasing Throughput

The speed of a Mattress Border Machine is one of its most impressive features. Today's models can operate at up to 1600 RPM, drastically outpacing manual sewing methods. This rapid operation translates directly to higher daily production rates.

When I implemented a fully automatic border machine in my factory, our throughput increased by approximately 40%. The machine's ability to continuously operate without frequent stops for adjustments made a huge difference.

Power consumption is another factor worth considering. Many newer models balance high-speed performance with energy efficiency. I've found that despite the increased production speed, the power usage per mattress produced actually decreased compared to older methods.

Most machines now feature:

Quick-change tooling for different border styles

Automated tension control systems

Programmable stitch patterns

Multiple needle configurations

Maintaining Consistent Quality

While speed is impressive, the real advantage comes from maintaining quality at high production rates. The best Mattress Border Machines deliver consistently neat stitching even at maximum sewing speeds.

Automated systems control tension perfectly across the entire border, eliminating the variation that often occurs with manual sewing. This consistency is especially important for premium mattress lines where visible stitching is part of the product appeal.

I've noticed that properly calibrated machines produce almost zero defects. The precision of modern border machines means rejection rates typically stay below 1%, even when running at full capacity.

Many manufacturers report labor savings of 50-70% after implementing automated border machines. This reduction in labor hours doesn't just save money—it removes the variability that comes with different operators handling the same materials.

Physical and Environmental Requirements

Setting up a mattress border machine requires careful planning for utility connections and workspace arrangements. Proper installation ensures optimal performance and operator safety when handling these specialized machines.

Power Supply Considerations

Most mattress border machines require a stable 220V or 380V three-phase power supply. I've found that machines typically consume between 1-3 kW of total power, depending on their size and capabilities.

It's essential to have dedicated circuits with proper amperage ratings for these machines. In my experience, a 20-30 amp circuit breaker is usually sufficient, but always check the manufacturer's specifications for your specific model.

Power fluctuations can damage sensitive electronic components, so I recommend installing a voltage stabilizer or surge protector. This small investment can prevent costly repairs down the line.

Remember to have a qualified electrician handle the initial installation. Proper grounding is critical for operator safety and machine longevity.

Air Pressure Needs

Many modern mattress border machines incorporate pneumatic components that require compressed air to function properly. The typical air pressure requirement ranges from 0.4-0.6 MPa (58-87 PSI).

Your air compressor should deliver at least 10-15 CFM (cubic feet per minute) to ensure smooth operation. I recommend installing:

Air filters to remove moisture and contaminants

Pressure regulators to maintain consistent pressure

Lubricators for pneumatic components if required by the manufacturer

An inadequate air supply can cause erratic machine behavior or component failure. I've seen this happen firsthand when factories try to run too many pneumatic machines on an undersized compressor.

Check all air lines regularly for leaks, which can reduce efficiency and increase operating costs.

Space and Weight Considerations

Mattress border machines are substantial pieces of equipment. Most models weigh between 200-500 kg (440-1100 lbs) and require adequate floor support. I always ensure my factory floor can handle this concentrated weight.

Space requirements vary by model, but you'll typically need:

Machine footprint: 2.5 × 1.5 meters (8.2 × 4.9 feet)

Operational clearance: 3.5 × 2.5 meters (11.5 × 8.2 feet)

Ceiling height: minimum 2.5 meters (8.2 feet)

The workspace must accommodate both the machine and the mattress handling area. I've found that a clear path around the entire machine makes maintenance much easier.

Good lighting is essential for operators to see their work clearly. I recommend 500-750 lux of task lighting in the immediate work area.

Safety and Maintenance Best Practices

Keeping your Mattress Border Machine running safely and efficiently requires regular attention and proper care. I've found that following structured maintenance routines not only extends the life of the equipment but also creates a safer working environment.

Routine Cleaning Procedures

I always start my weekly maintenance by disconnecting the power supply. Safety first! The machine collects fabric particles and dust that can affect performance, so I use compressed air to clean hard-to-reach areas.

For the exterior surfaces, I wipe them down with a damp cloth—never soaking wet to avoid electrical components. The sewing heads need special attention, as lint buildup can cause thread breakage and skipped stitches.

I make it a point to clean and oil the needle bar assembly after every shift. This simple step has saved me countless headaches. For metal parts showing signs of rust, I use a manufacturer-approved rust remover followed by a thin coat of machine oil.

Monthly deep cleaning checklist:

Remove and clean bobbins and bobbin cases

Clean thread guides and tension discs

Vacuum motor vents

Inspect belts for wear and clean

Check and clean foot pedals

Essential Safety Precautions

I never operate my Mattress Border Machine without proper training. The fast-moving parts can cause serious injuries if mishandled.

I always wear close-fitting clothing and tie back long hair to prevent entanglement. Safety glasses are non-negotiable when operating or cleaning the machine, especially when using compressed air.

The emergency stop button location should be memorized by every operator. I test it monthly to ensure it's working properly. When performing maintenance, I use lockout/tagout procedures to prevent accidental startup.

Guards and safety shields must remain in place during operation. I've seen too many injuries from people removing these "for convenience." It's never worth the risk.

Machine modifications are a big no-no. I only use manufacturer-approved parts and attachments designed specifically for my model of Mattress Border Machine.

Troubleshooting Common Issues

When thread breaks frequently, I first check if the machine is threaded correctly. Then I inspect for rough spots on thread guides or tension discs. Dull or bent needles are often culprits too.

If the border looks uneven or puckered, I check the presser foot pressure and fabric tension. Sometimes adjusting the feed dogs solves this issue right away.

Unusual noises from the machine require immediate attention. I stop operating and check for loose parts or foreign objects. A grinding sound often indicates a lack of lubrication.

For motor issues, I check:

Power connections

Foot pedal functionality

Belt tension and wear

Motor brushes (if applicable)

Electrical problems like intermittent power require professional help. I never attempt to repair electrical components myself—that's a job for qualified technicians who understand the specific requirements of a Mattress Border Machine.

Selecting the Right Mattress Border Machine

Choosing an appropriate mattress border machine requires careful consideration of your specific manufacturing needs, technical capabilities, and ongoing support requirements. The right equipment can significantly impact production quality, efficiency, and your mattress brand's reputation.

Assessing Manufacturer Needs